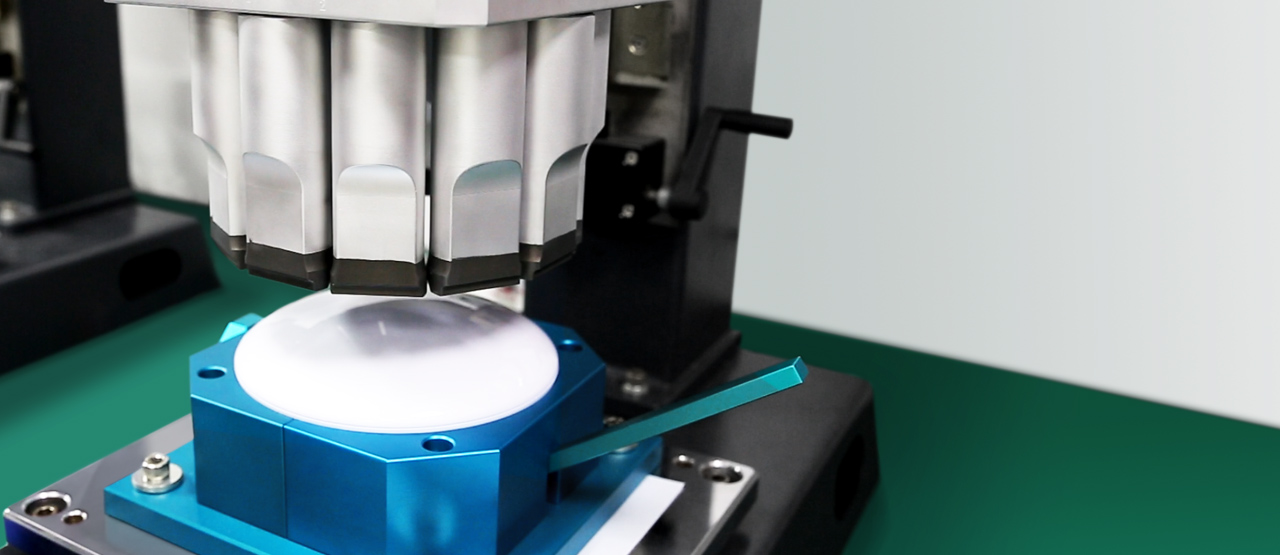

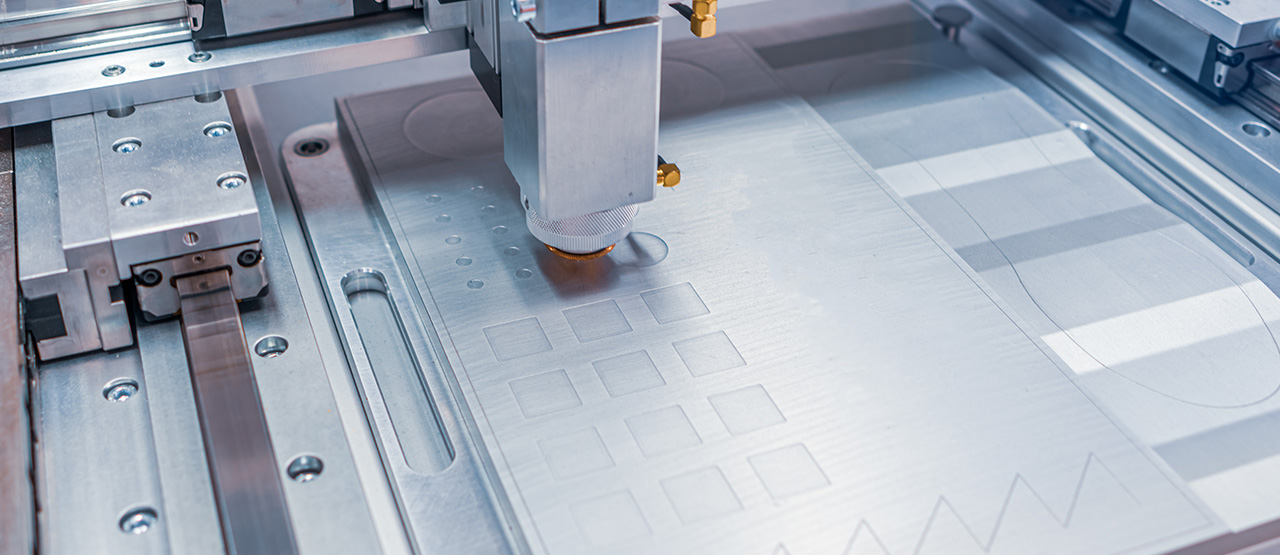

Ultrasonic welding is demonstrating increasingly clear advantages in the packaging industry. Packaging materials are sealed after being heated under ultrasonic vibration at a high frequency of 20~40 kHz, which demonstrates a pretty clear advantage in sealing compared with thinner or thicker packaging materials. It not only shortens the welding time and improves efficiency, but also saves energy and packaging materials.

Ultrasonic welding & sealing: food packaging, medical packaging, valve bag packaging, PE packaging, FS packaging, nonwoven packaging, leather packaging, composite film packaging, and so forth.

Without heating elements, each package solely consumes 0.1s electric energy; without preheating time, the time it takes to seal materials is short; the excellent performance in sealing contaminants allows products previously canned or bottled to be packaged flexibly.