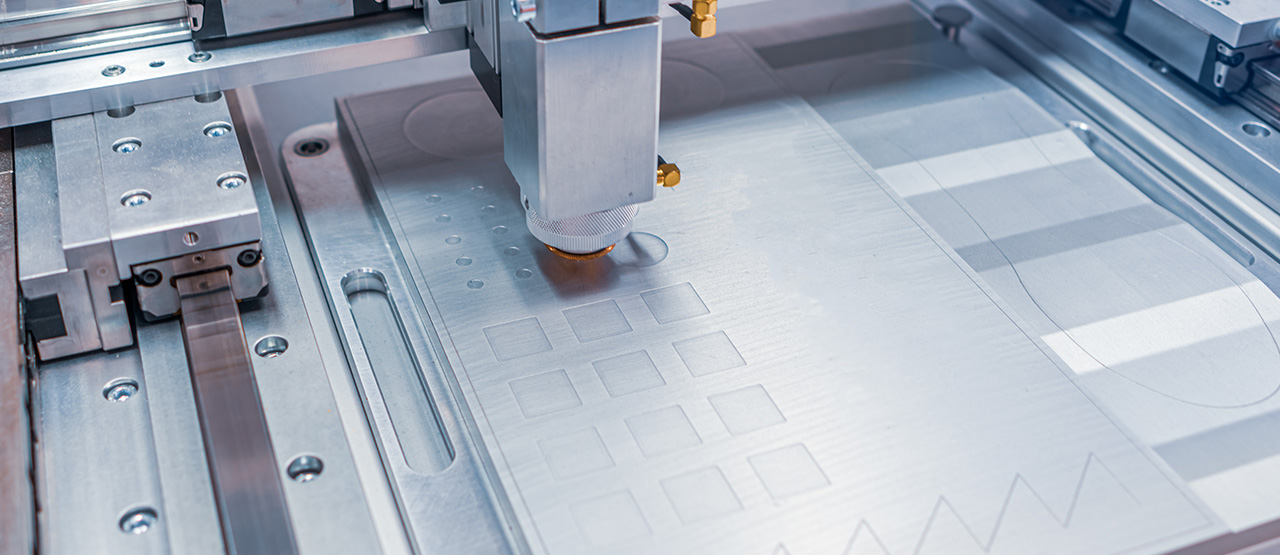

Advantages: fast welding speed, high welding strength, and excellent sealing performance; replacing the traditional welding/bonding technique, clean and pollution-free with no damage to workpieces.

Stable welding process; all welding parameters trackable and monitorable through software system; faults once found easy to troubleshoot and repair.

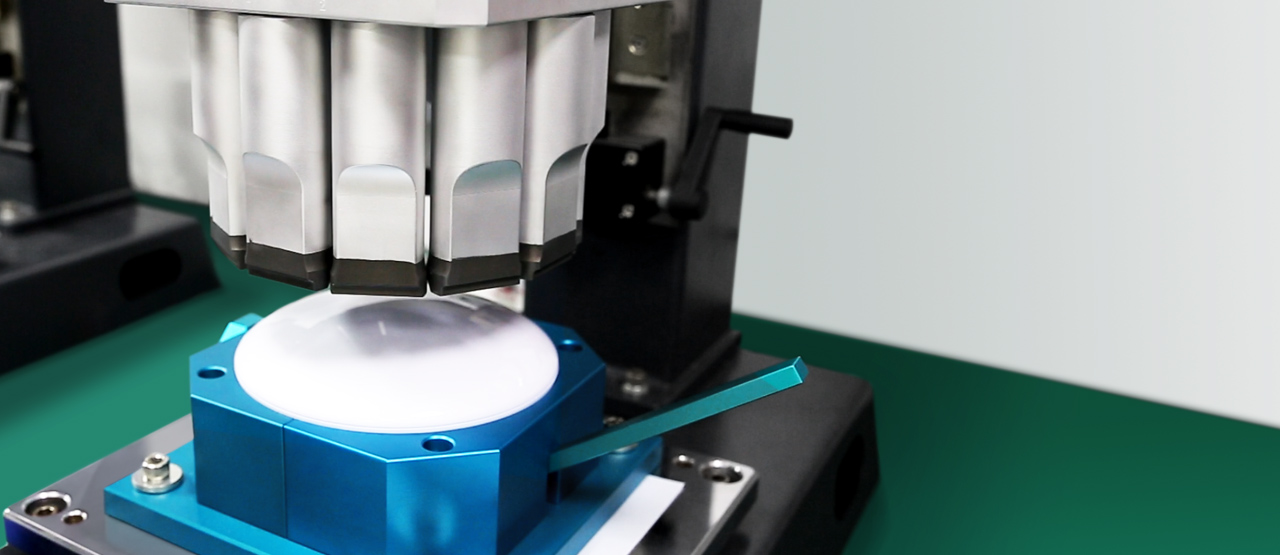

The ultrasonic welding machine converts electronic energy into mechanical energy through sonic vibration and then transmits the mechanical energy to the plastic surface through the sonotrode so that heat is generated by intense friction between molecules to fuel the product to melt and integrate instantaneously. It renders the processing fast, clean, economical, and eco-friendly. It performs cutting with little noise, so no noise control measures are required.