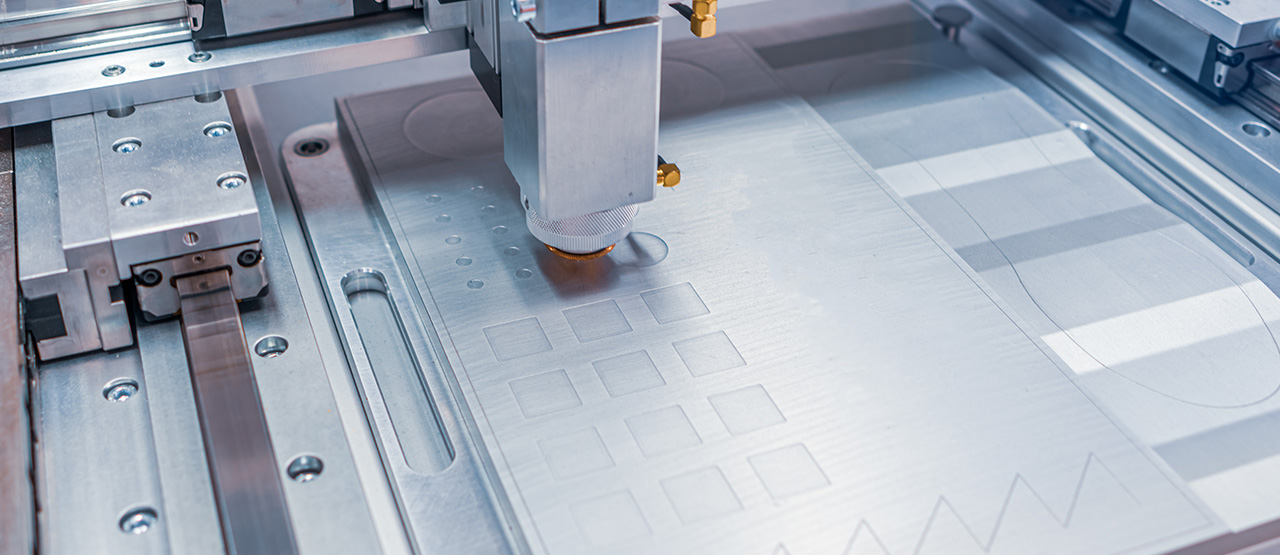

Ultrasonic cutting is quite different from general cutting. While ensuring accurate cutting, ultrasonic cutting technology does not destroy cut products, preserving their integrity to the greatest extent. A four-axis drive system with an accurate and fast servo driver drives the ultrasonic cutter to cut more quickly and reduces the energy consumed by the ultrasonic cutter. Applying ultrasonic cutters to the industrial process can minimize the cutting time and maximize efficiency and productivity.

The ultrasonic cutter performs cutting with so little noise that there is no need for noise abatement equipment and without causing personal injuries. It does not adversely affect the ecosystem. Its use has been universally proven to be non-hazardous in industrial environments. Ultrasonic cutting is a reliable technology showing respect for the environment.

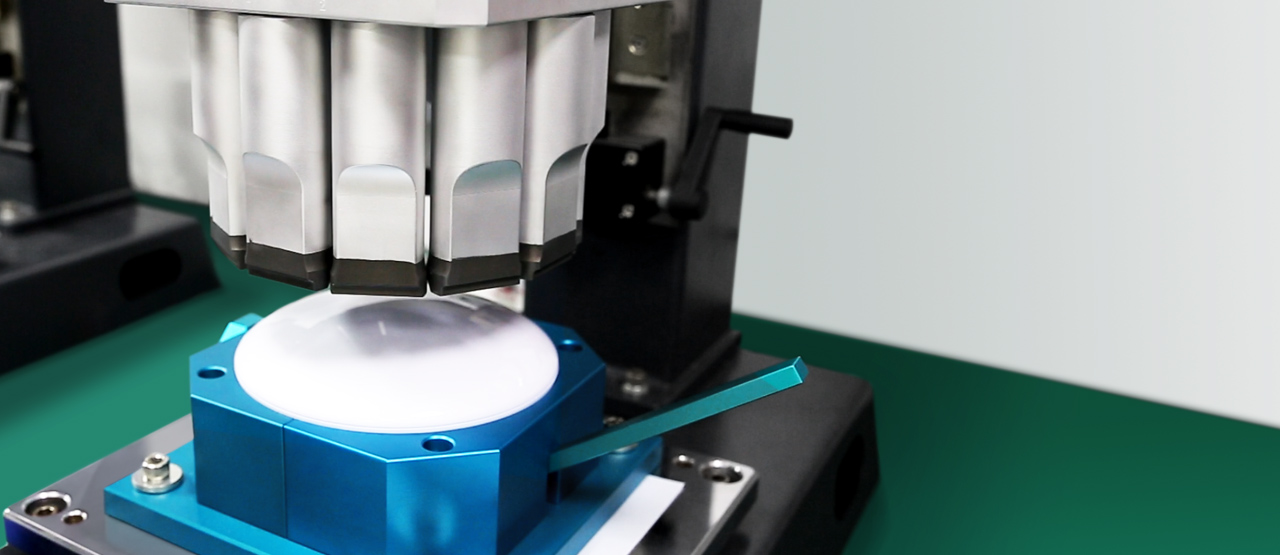

Ultrasonic cutting achieves much better cutting quality than traditional cutting. The ultrasonic cutter features such a pretty high precision that it better adapts to a variety of cutting restrictions in industrial environments. The ultrasonic cutter is so compact, convenient, and flexible that it works with a mechanical arm or a piece of automation equipment, which allows for food cutting at any angle and ideal food forms to the greatest degree.