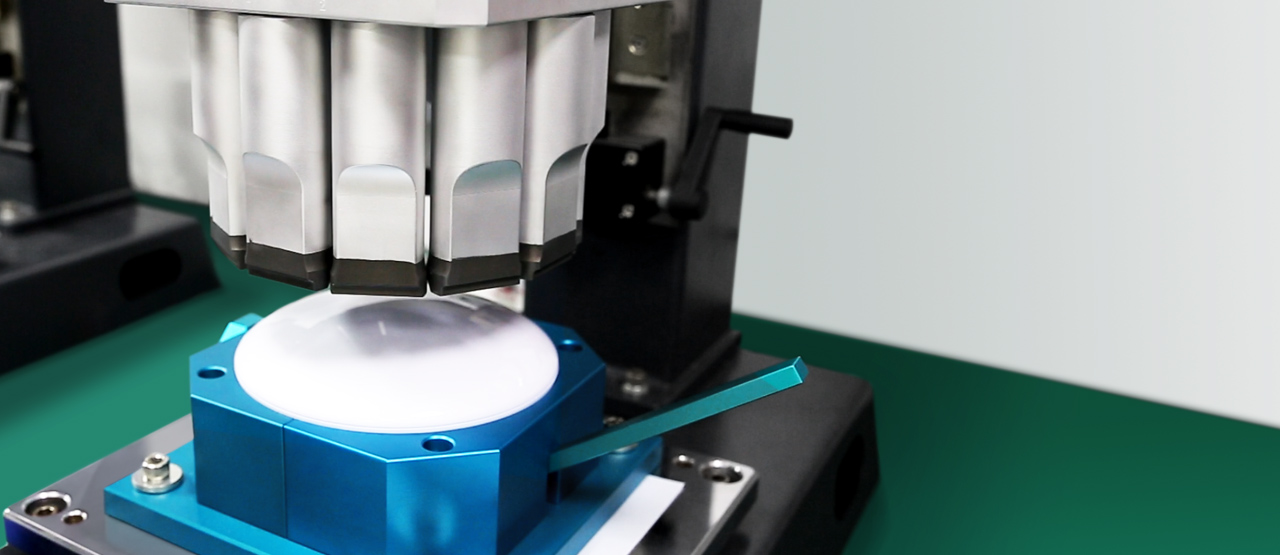

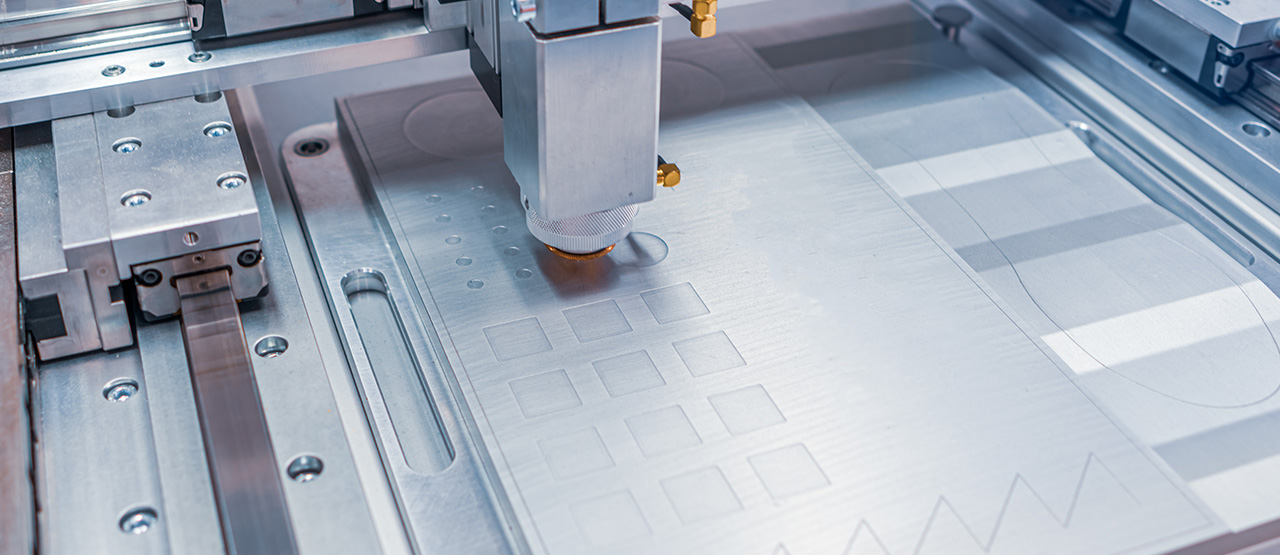

Ultrasonic welding is, absolutely, the most ideal for non-adhesive laminated materials. Products that have been welded feel good to touch and their material softness remains.

Ultrasonic technology is used for diaper connection. Its special feature is utilized to connect elastic tabs or left and right stickers with the diaper body, reinforcing the connection. This ensures a diaper product is fabricated without the use of any chemical adhesive agent, which not only saves materials but also makes the product more eco-friendly. Elastic rubber bands for diapers (disposable diapers/pull-ups) are welded by ultrasonic elastic wire welding technology. Diapers fabricated in this way may be without ligature marks, sagging, and side leakage. They are stitched without adhesive, rendering them more comfortable and less allergic.