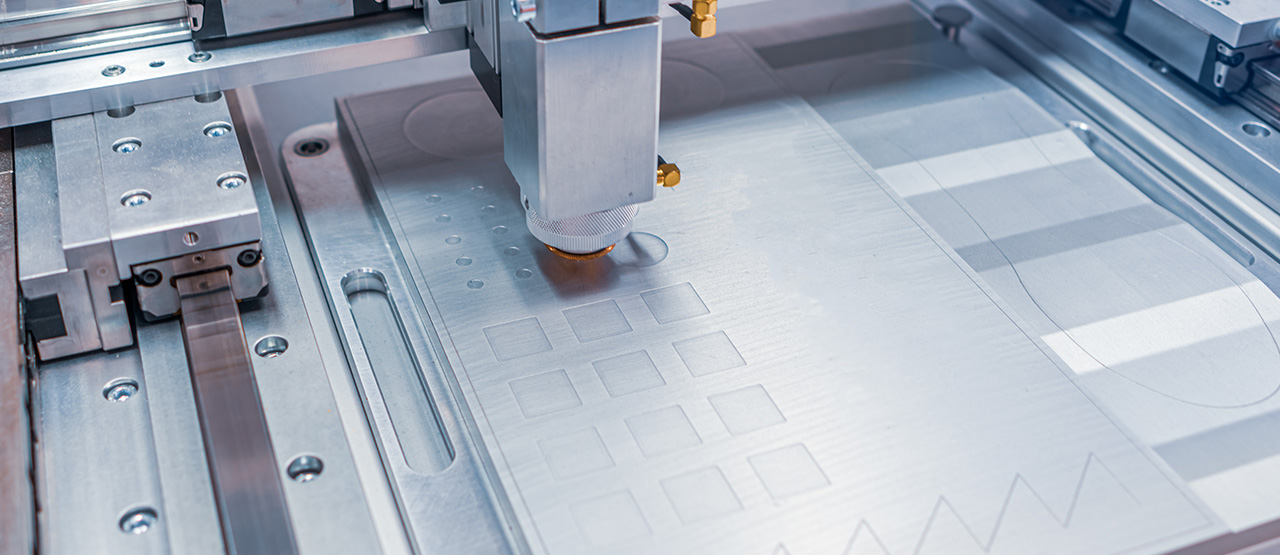

The cutting & sealing ultrasonic technique is a proven and well-established technology for cutting and connecting various substrates. It has been applied to a great many products such as filtration, clothing, medical, wound care, and healthcare products.

Many finished products made from multi-layer substrates must be free of frayed edges, loose yarns, or delamination in service. In some cases, in addition to products' aesthetics and intactness, products' edges shall be made smooth, which is of great significance for close contact between products and skin. The cutting & sealing technique meets all the aforesaid requirements, so it is pretty popular among manufacturers in a great many industrial fields.

Trimming is not required, for there is no material loss and cuttings, and cut edges are smooth and clean. In addition, the ultrasonic cutting technique performs cutting with little noise, so no noise control measures are required.