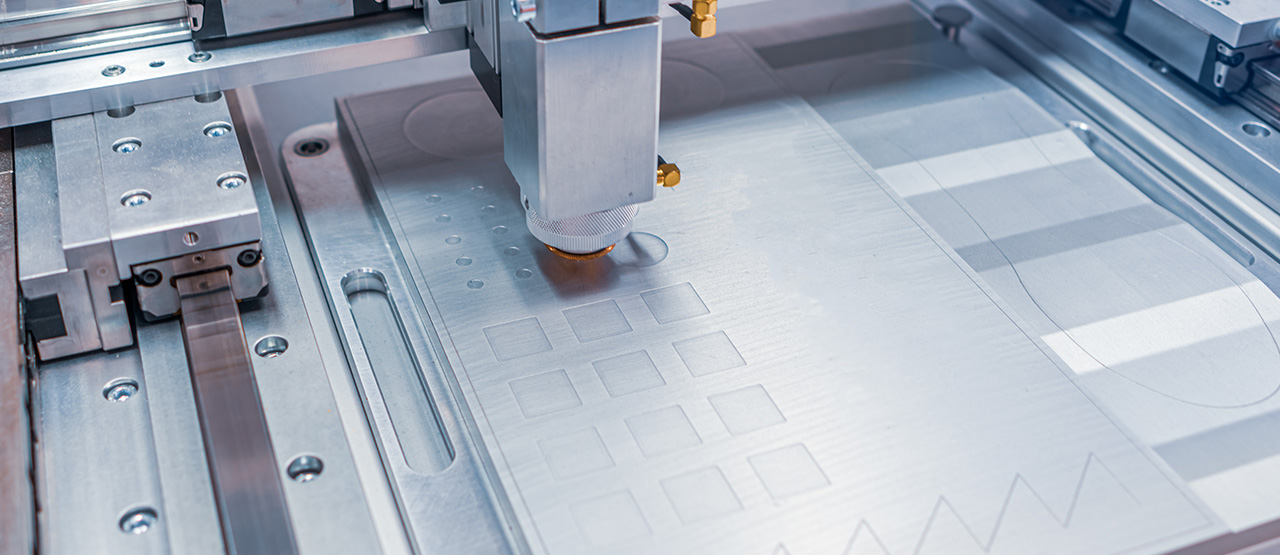

When it comes to welding and stitching nonwovens, the ultrasonic welding technique works to locally cut and seal textiles in a tidy manner, without needle & thread; textiles are not only stitched but also decorated, with so strong adhesion that a waterproof effect is achieved, with so clear embossments that textile surface looks more stereoscopically embossing. The technique works swiftly and makes products more aesthetic.

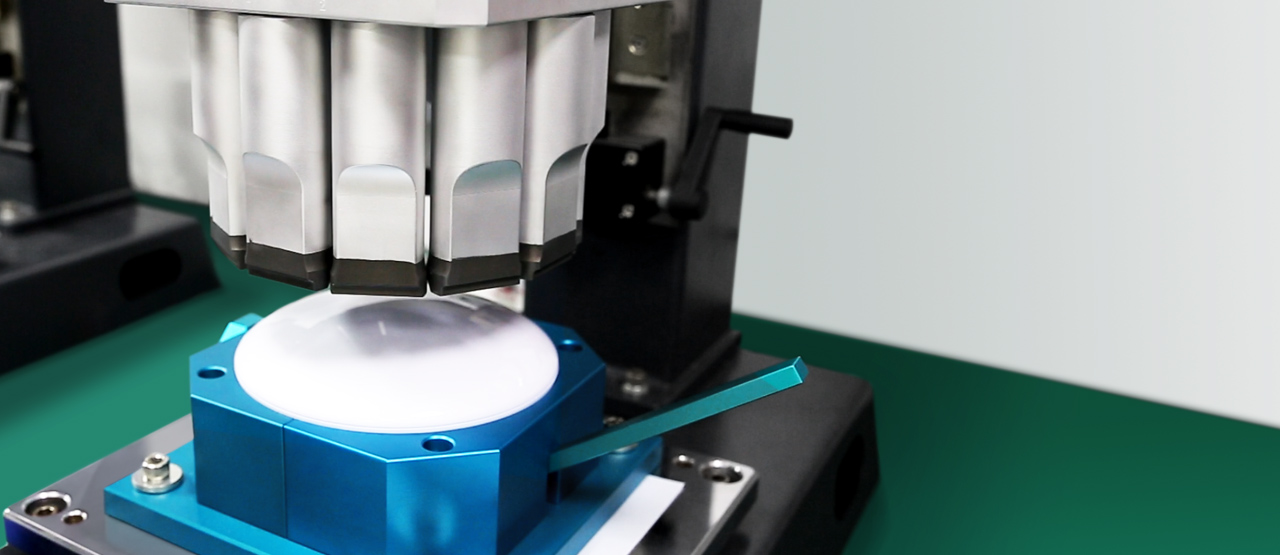

Ultrasonic technology is used for diaper connection. Its special feature is utilized to connect elastic tabs or left and right stickers with the diaper body, reinforcing the connection. This ensures a diaper product is fabricated without the use of any chemical adhesive agent, which not only saves materials but also makes the product more eco-friendly. Elastic rubber bands for diapers (disposable diapers/pull-ups) are welded by ultrasonic elastic wire welding technology. Diapers fabricated in this way may be without ligature marks, sagging, and side leakage. They are stitched without adhesive, rendering them more comfortable and less allergic.